JJ@WMS

Well-Known Member

- Joined

- Aug 22, 2014

- Threads

- 38

- Messages

- 287

- Reaction score

- 86

- Location

- Woodbine MD

- Vehicle(s)

- 2015 EB Mustang

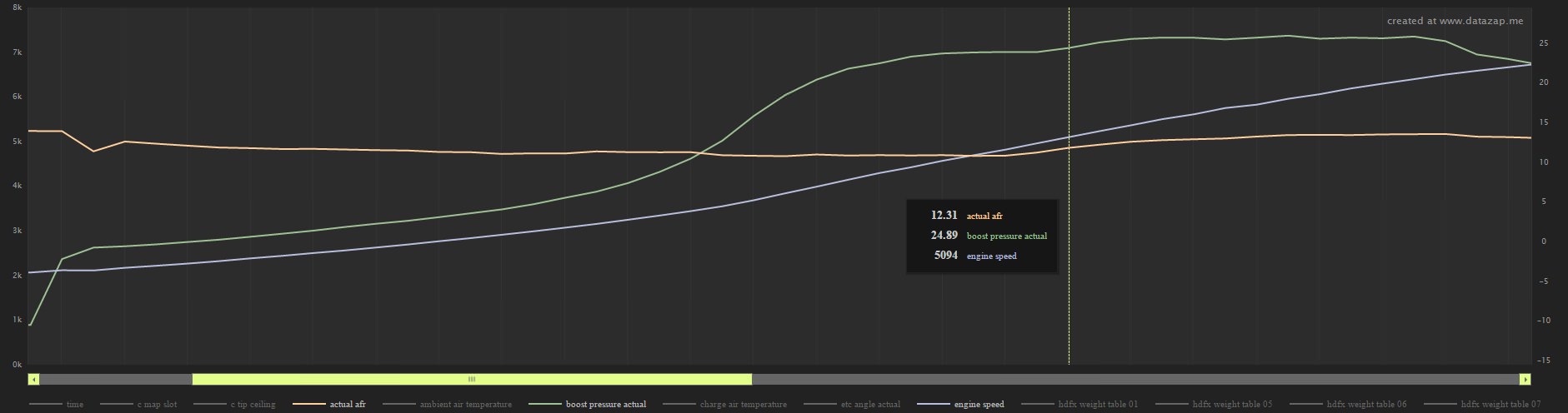

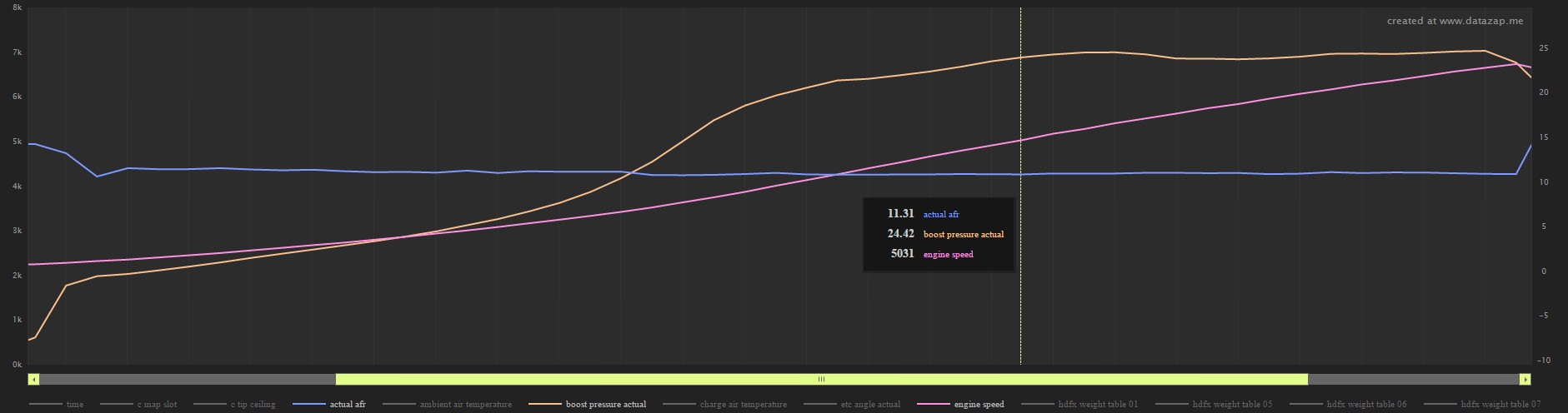

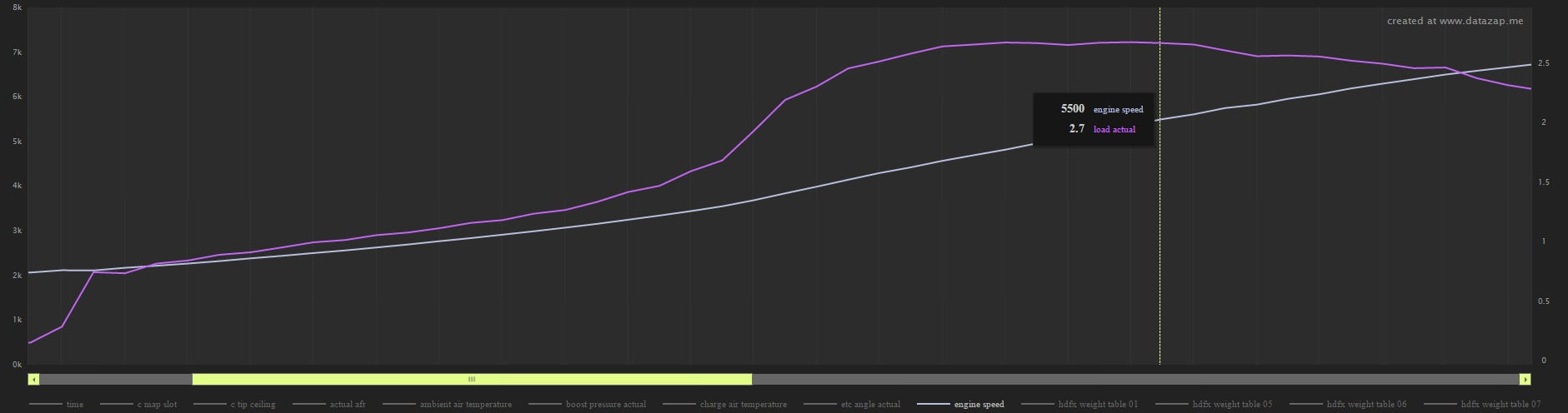

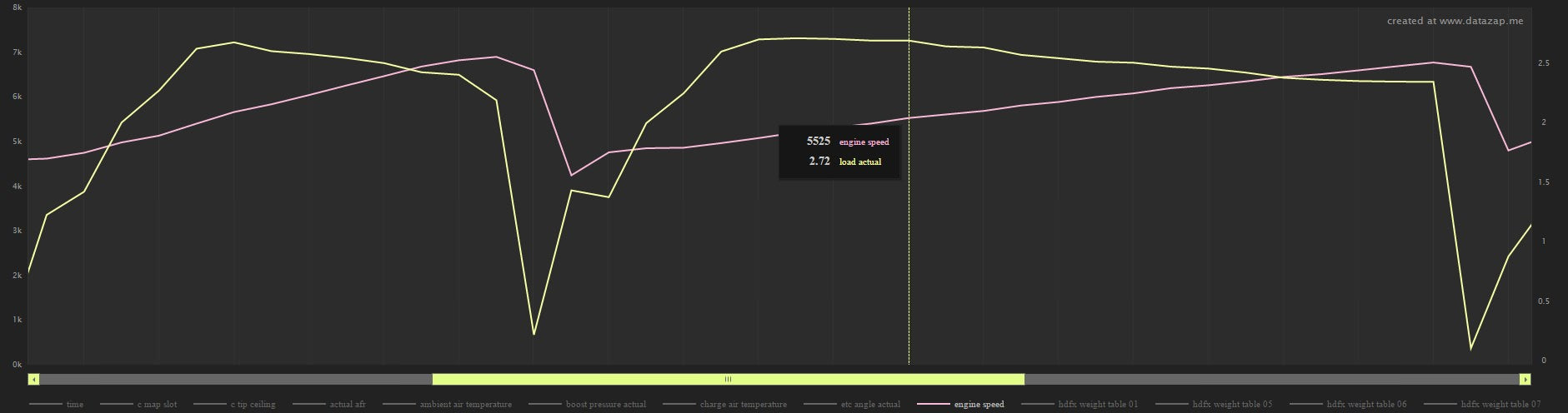

Nobody has fueling issues on an unloaded dyno. We were able to make 370/400 on our dyno with no problem but under real world load the fueling issues will show themselves as they have with other tuning companies that have tested at the track. Even Livernois has stated fueling is an issue at higher boost/power levels.Yeah hoping to hear something soonI find it interesting ma performance doesn't seem to have fueling issues with their upgrade. :shrug:

The statements that fueling isnt an issue "even with E85" have yet to be proven. If and when its proven otherwise I will gladly eat my words but until then I will stand by the fact that proof and data mean more to me then unsubstantiated statements.

If our car laid down tons of power on E85 with no fueling issues you bet your butt we would be at the track with it to show what it could do.

JJ

Sponsored