MAPerformance

Well-Known Member

- Joined

- Jan 14, 2015

- Threads

- 137

- Messages

- 1,681

- Reaction score

- 999

- Location

- Cottage Grove, MN

- Website

- www.maperformance.com

- First Name

- Sales

- Vehicle(s)

- 2015 Ecoboost Base w/ Performance Package

- Thread starter

- #46

That's pretty shocking. The 25 lb figure came from what I assumed to be a general rule of thumb: Aluminum will weigh 1/3 of stainless. I've built several competition race cars including two current ones I own, as well as discussed such topics with other pro teams and all pretty much agree on that. You're now making me question if the world is round. Haha.

Thank you for taking the time to weigh the parts!

Not a problem Leon, I have no problem explaining why we do things. That is the point of this thread. I prefer people to challenge me, it ultimately makes a better product in the end and that is our goal.

I wouldn't question that the world is round, and I wouldn't question your builds. Aluminum is fine, everything has its pros and cons. There is absolutely nothing in our industry that doesn't have a handful of pros and a handful of cons, that is the point of testing and chose the one with the most benefits! For us, it's stainless.

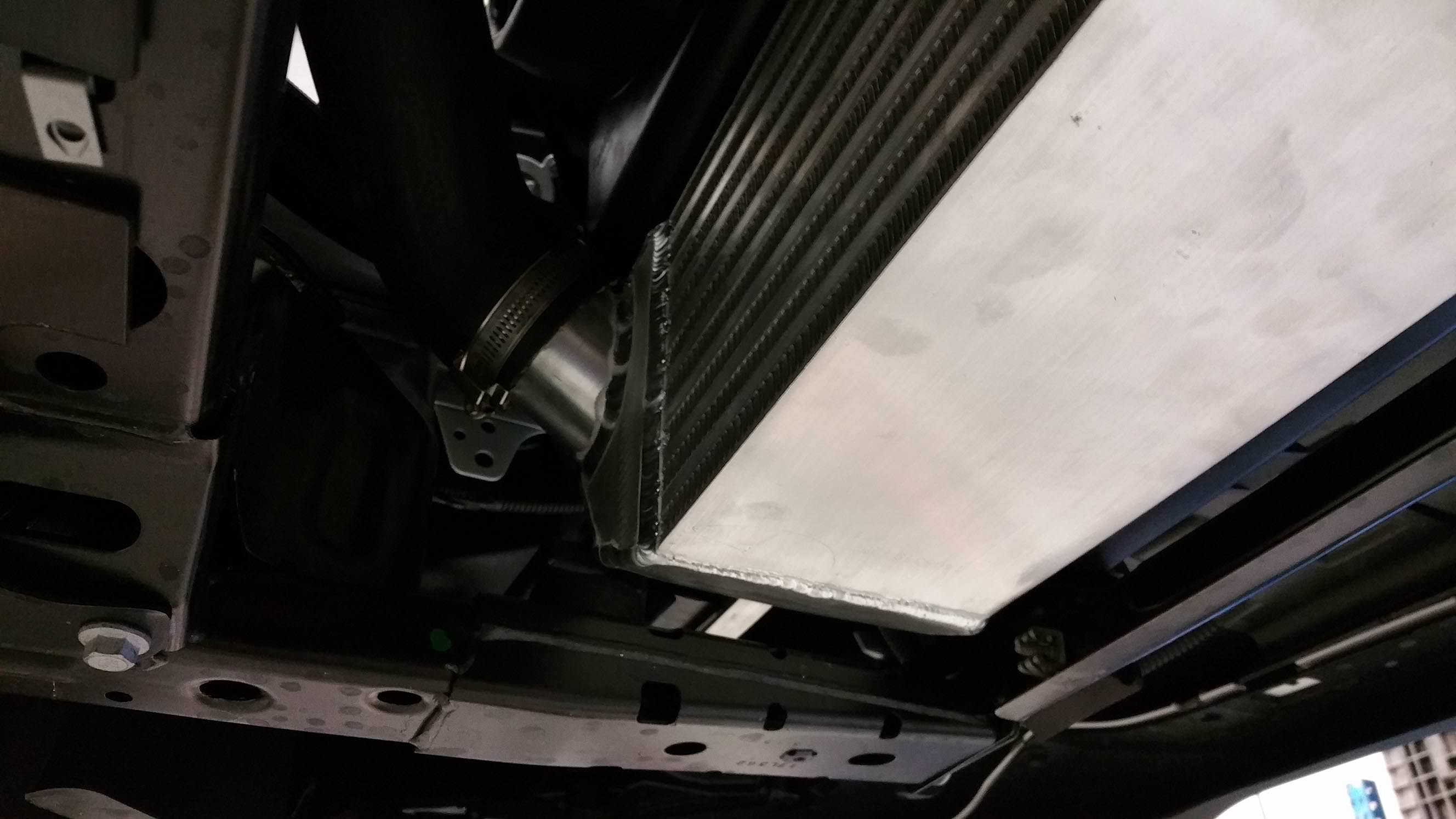

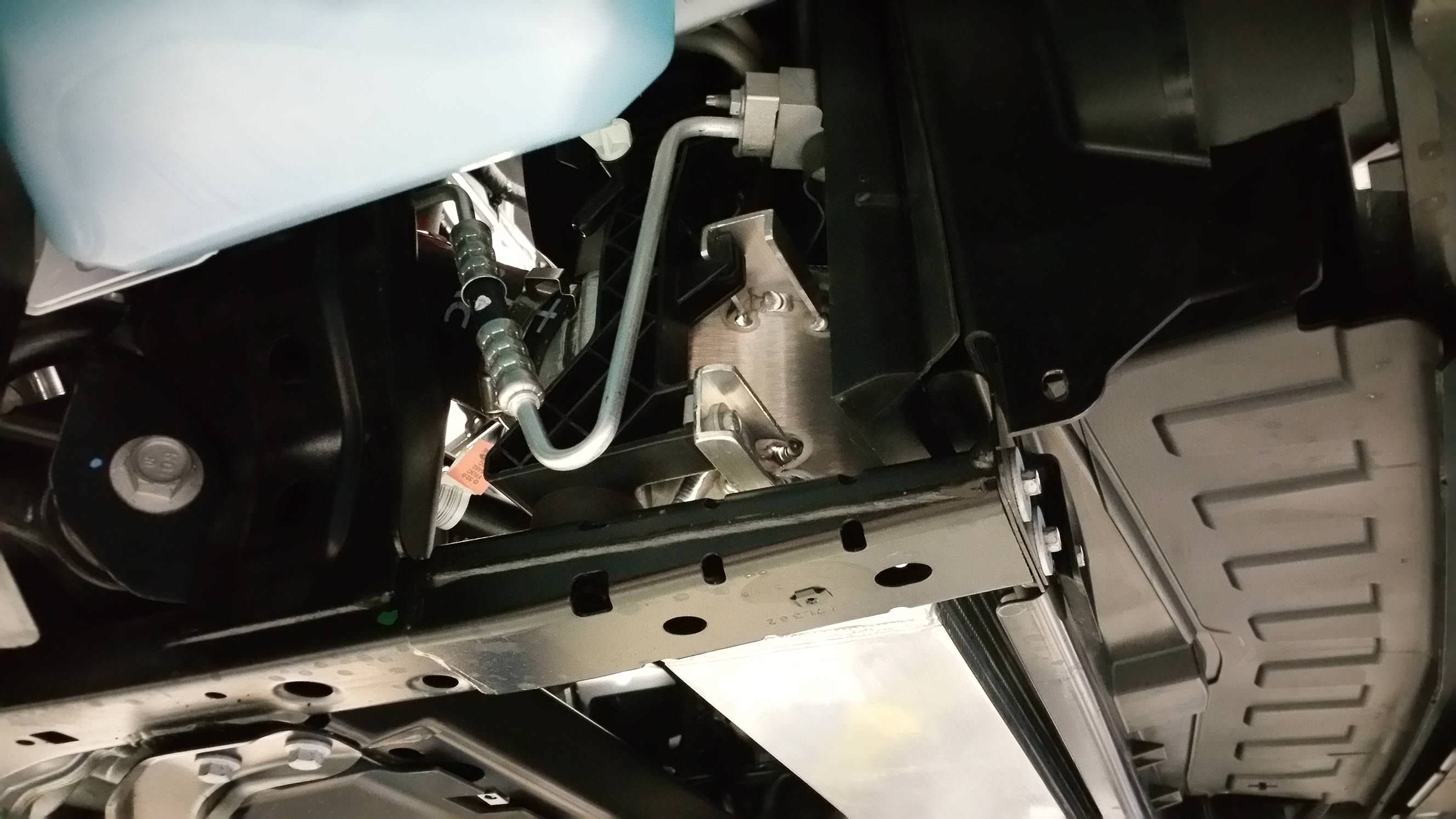

One thing I forgot to mention on the positive side of steel, is that we are dealing with contents under pressure. We are going to be supplying t-bolt clamps with our intercooler piping, which can easily crush an aluminum pipe and cause it to oval. When something gets oval'd that is intended to be round it is fatigued and is prone to failure. In the case of charge piping it can cause boost leaks, or if pressurized too much after oval'ing it can split/crack. Steel doesn't crack, or split for that matter.

Good conversation, again I appreciate it!

-Adam Brunson

Sponsored