MAPerformance

Well-Known Member

- Joined

- Jan 14, 2015

- Threads

- 137

- Messages

- 1,681

- Reaction score

- 999

- Location

- Cottage Grove, MN

- Website

- www.maperformance.com

- First Name

- Sales

- Vehicle(s)

- 2015 Ecoboost Base w/ Performance Package

- Thread starter

- #31

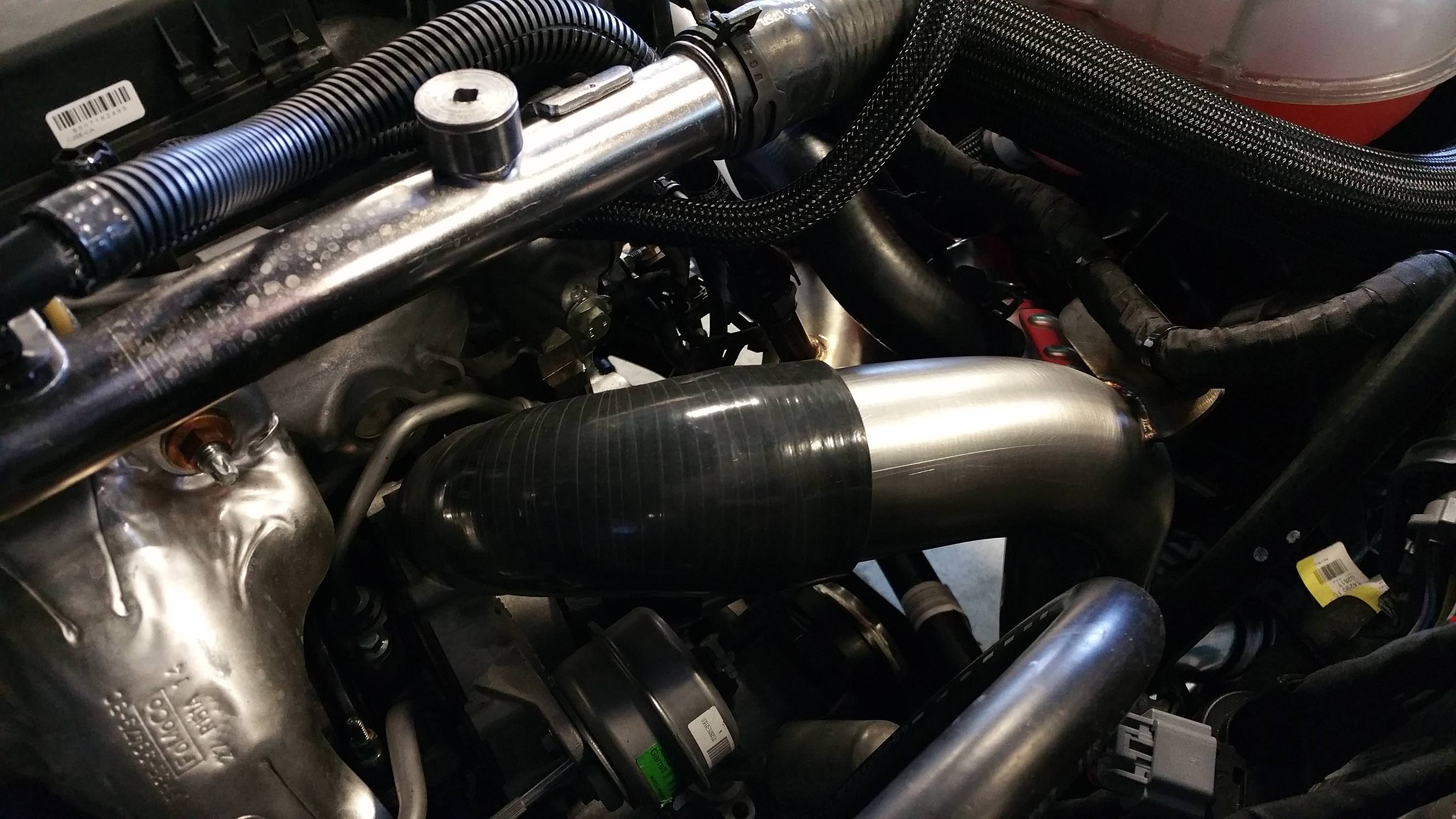

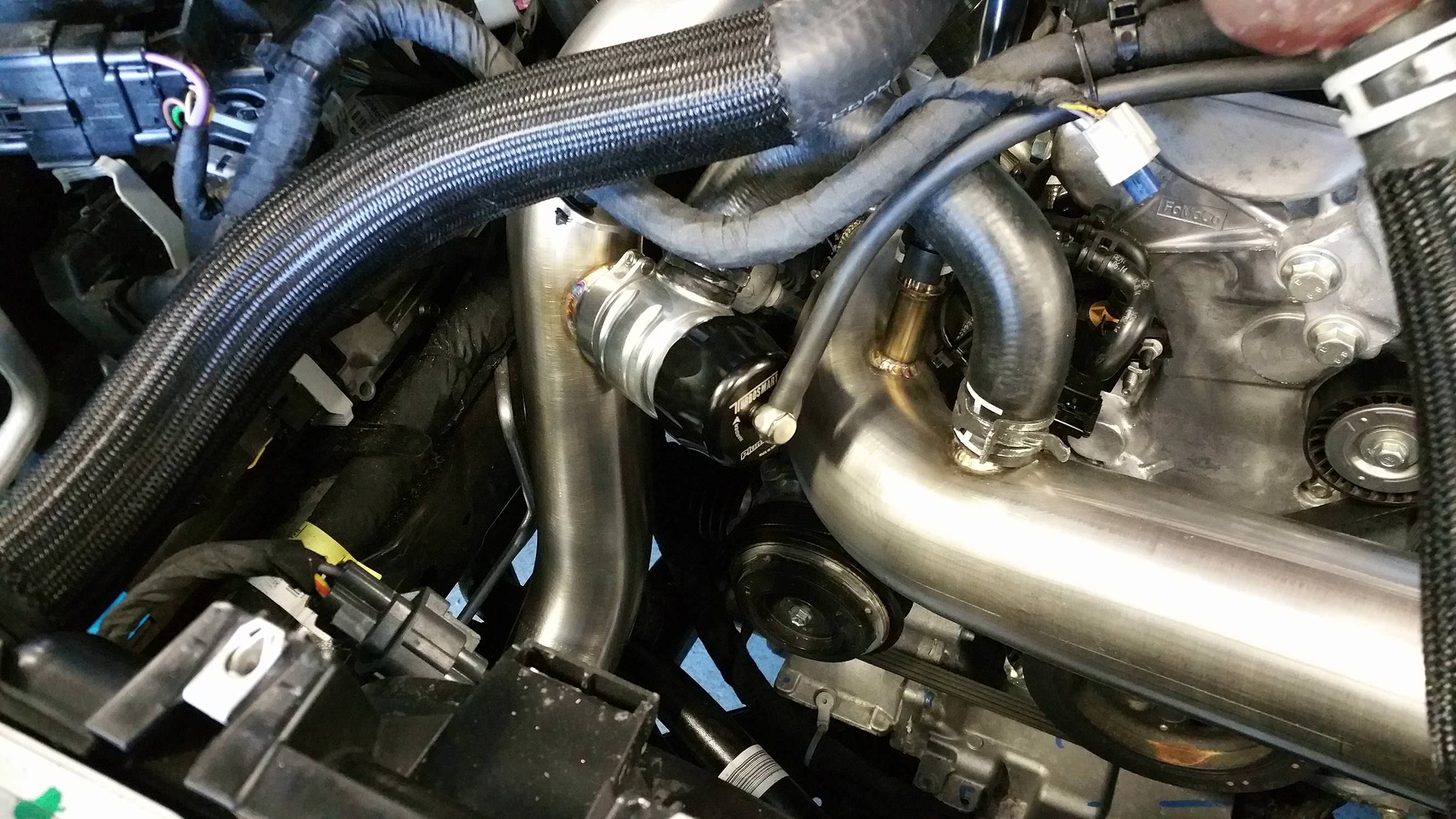

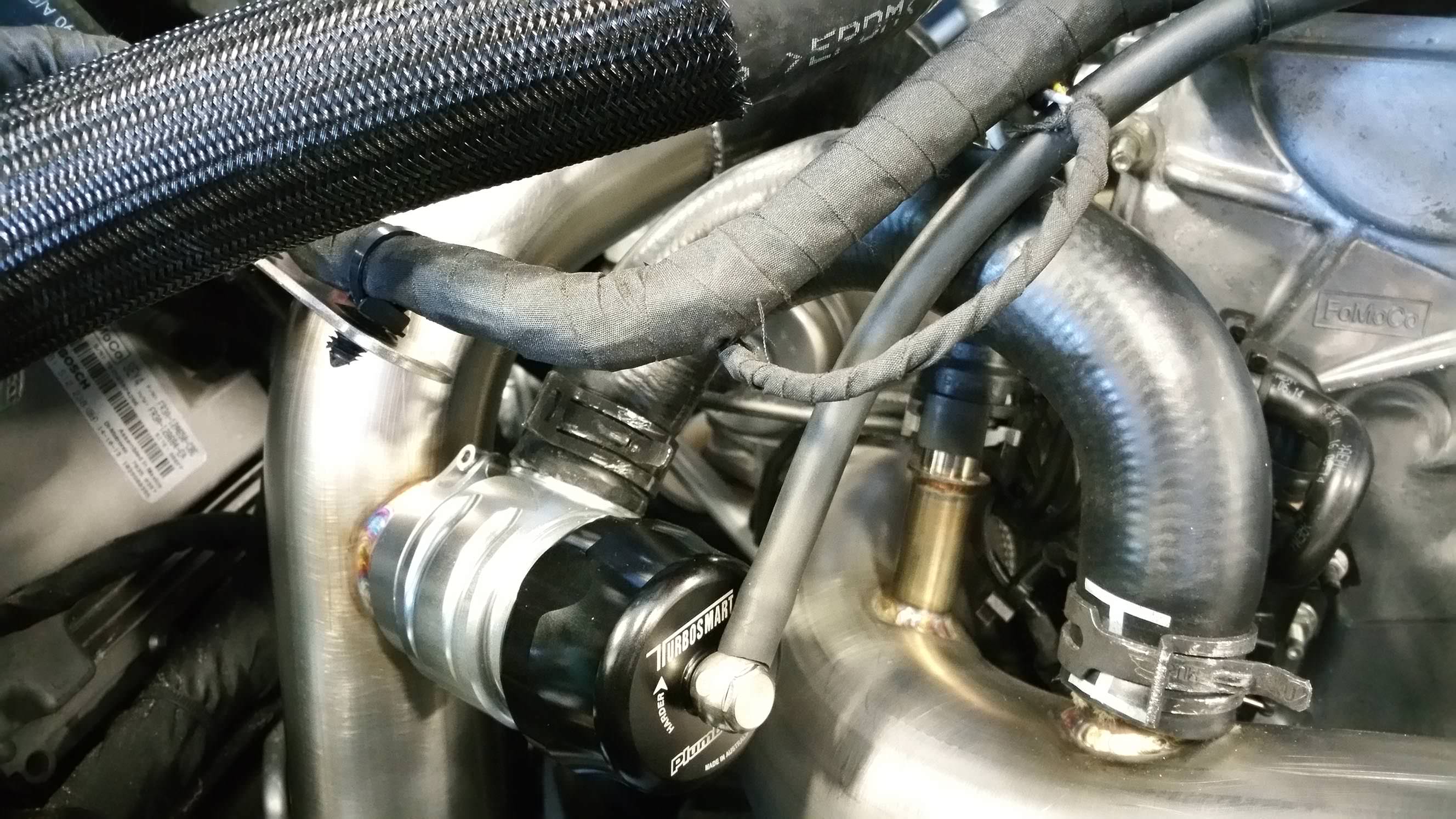

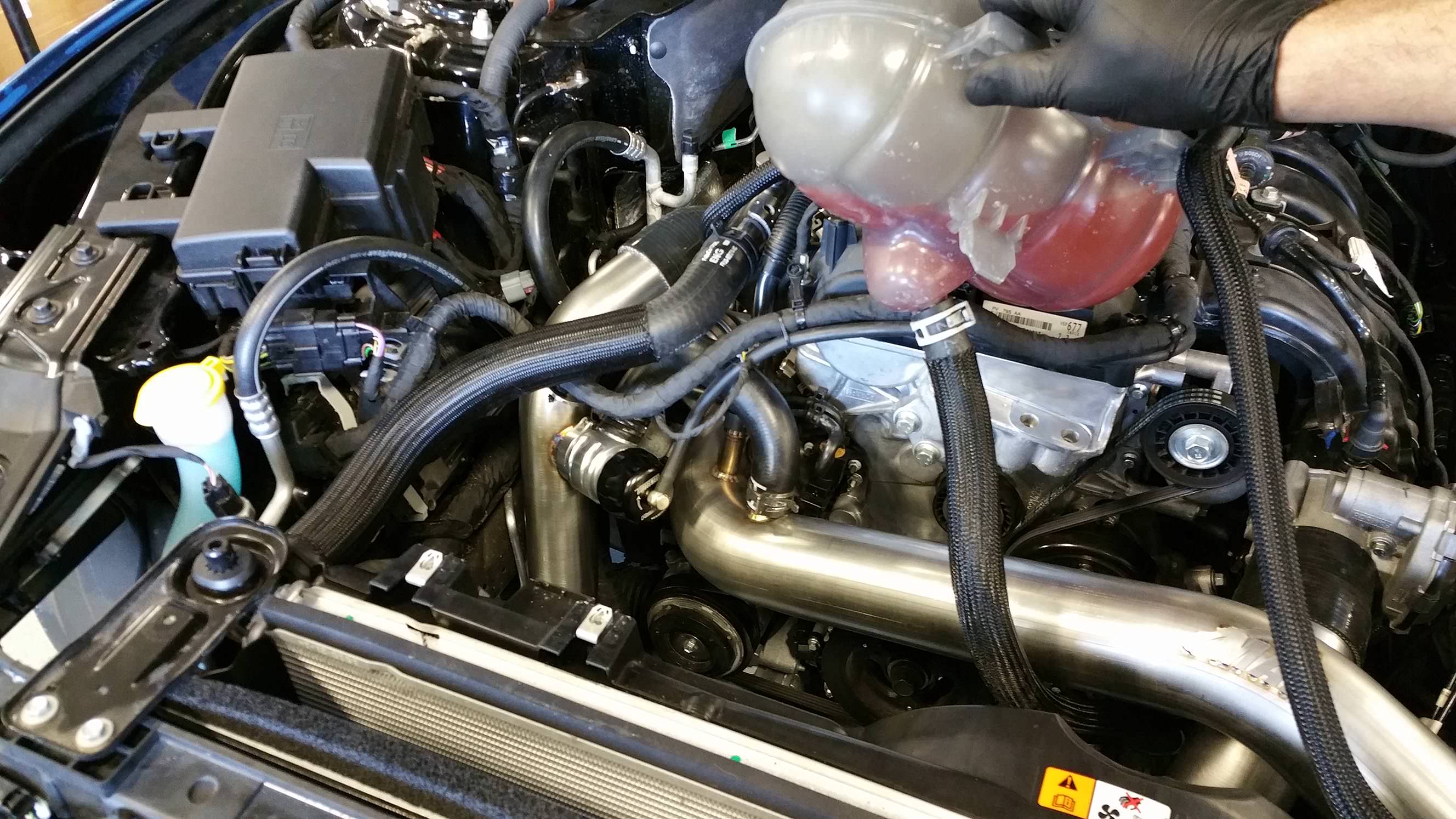

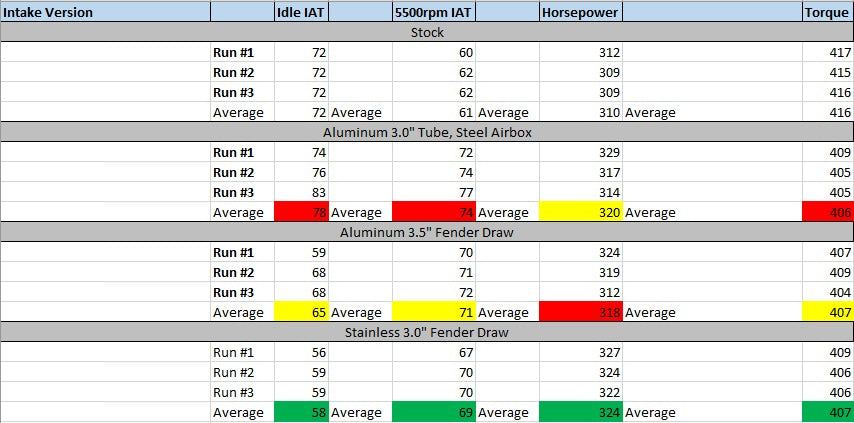

As far as I know, we are the only company that are going to be offering full packages utilizing our own in house products. Our Phase 1 package (Intake, Downpipe, Catback, Accessport, and Custom Tune) will be released this week, granted everything goes wells on the dyno tomorrow!Looking forwards to the results!

That's how I'm feeling at this point too. I'm waiting to see who comes out with the most attractive package/stage "x" kit by year's end. It's going to be hard to wait but I think it will be smarter to do so in the long run.

Sponsored

Plan on getting on the dyno tomorrow at 2:00pm and if everything goes according to plan I can use Wednesday to setup the release!

Plan on getting on the dyno tomorrow at 2:00pm and if everything goes according to plan I can use Wednesday to setup the release!