RSPEC-015

Well-Known Member

- Joined

- Mar 18, 2015

- Threads

- 5

- Messages

- 1,021

- Reaction score

- 703

- Location

- Sydney, Australia

- Vehicle(s)

- Ford Territory & Mustang GT

- Thread starter

- #1

Hi Guys,

Greetings from Australia!

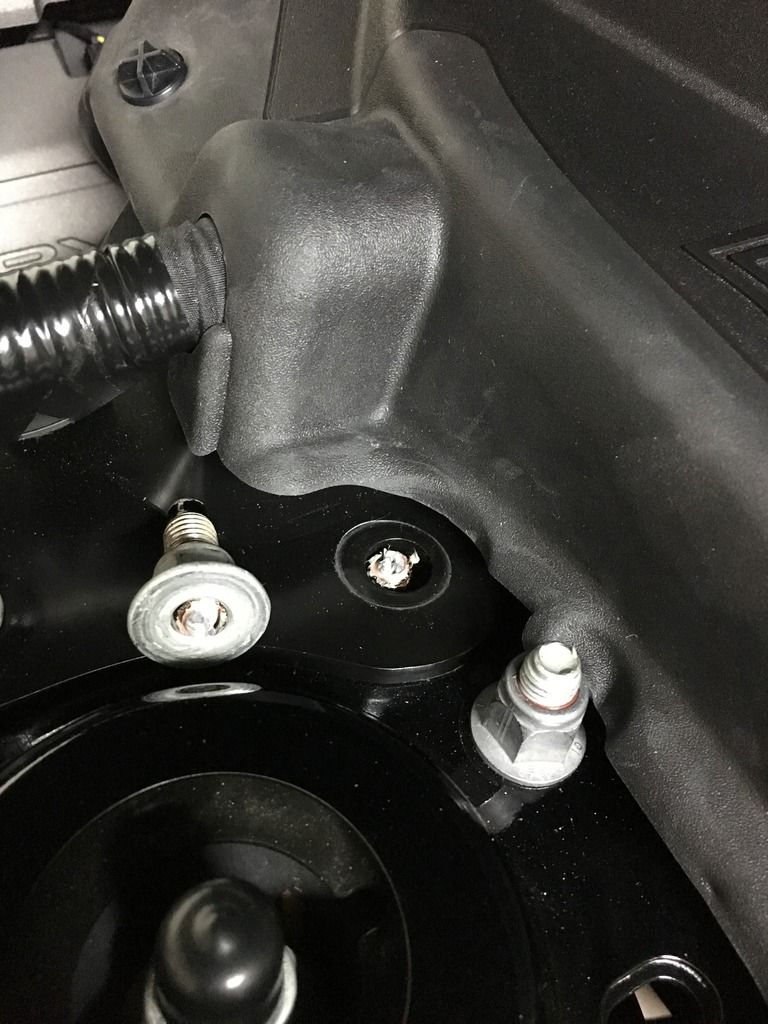

About a week ago I fitted a Steeda strut tower brace to my Mustang GT. I wasn't happy with the fit of the nuts supplied with the brace. They "bit" into the steel and didn't really cover the mounting slots sufficiently.

I wasn't happy with the look and yesterday decided to remove it. I put back all the factory nuts and 7 of the 8 nuts tightened satisfactorily with my torque wrench. When trying to tighten the 8th nut I sheared off the thread. Main thing is it's not a nut associated with the strut.

Just wondering if anyone has had a similar thing happened and how to fix it? I've tried searching the front suspension but can't find any reference to the bolts. These also hold down the K-Brace which is standard on Mustangs shipped to Australia.

Any info would be appreciated.

Cheers & Thanks

Jim

Greetings from Australia!

About a week ago I fitted a Steeda strut tower brace to my Mustang GT. I wasn't happy with the fit of the nuts supplied with the brace. They "bit" into the steel and didn't really cover the mounting slots sufficiently.

I wasn't happy with the look and yesterday decided to remove it. I put back all the factory nuts and 7 of the 8 nuts tightened satisfactorily with my torque wrench. When trying to tighten the 8th nut I sheared off the thread. Main thing is it's not a nut associated with the strut.

Just wondering if anyone has had a similar thing happened and how to fix it? I've tried searching the front suspension but can't find any reference to the bolts. These also hold down the K-Brace which is standard on Mustangs shipped to Australia.

Any info would be appreciated.

Cheers & Thanks

Jim

Sponsored