Moving back and forth is normal on smooth idlers as they have no ribs to guide them.So last night around 1:30 am I couldn't sleep due to this thing pissing me off, so I pulled it apart and removed the .070 shims then re assembled it. The belt is now riding in the middle of the supercharger pulley as it is supposed to. After pulling it all apart and inspecting everything I have come to this conclusion my original tensioner was not running true to the mounting point therefore the combination of the shim and the tensioner being tweaked rearward was keeping the belt on the supercharger pulley, then when I put the new tensioner on it was machined true and it forced the belt to move forward making it skip one rib forward on the supercharger pulley. Now by removing the shim it has brought the belt back to it's normal position on the supercharger pulley.

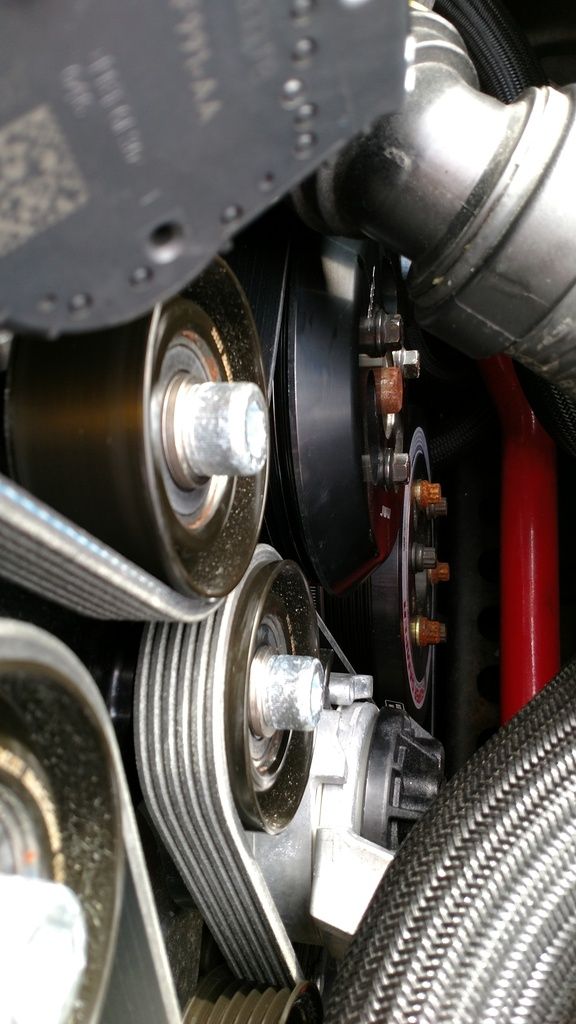

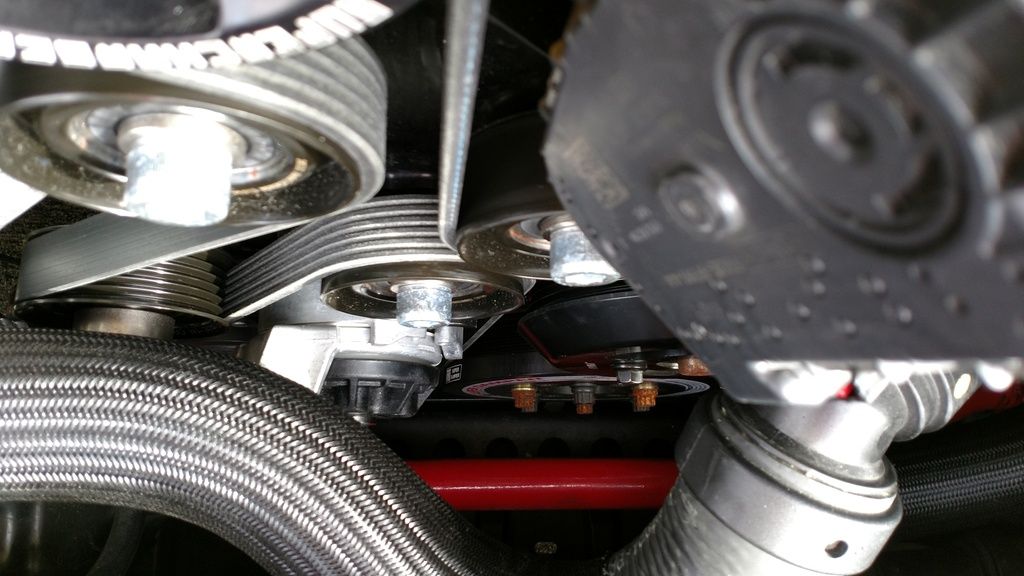

Now this is the part that needs an explanation I have verified via a straight edge that my ATI damper, water pump pulley and supercharger pulley are all in alignment. Why is the belt riding to the very back of the smooth idler that is closest to the tensioner and this is where the belt rides one rib off when compared to the water pump pulley. Yet when the belt rides over the top 2 idlers that are beneath the supercharger pulley the belt rides parallel and the belt is close to the middle of the smooth idler with equal gap on both sides. And yet the belt rides to the very back edge of the smooth idler closest to the tensioner ? I would like an explanation for this I believe that it is due to the design of the idler bracket and the proximity of the 3 idlers and the tensioner being so close to each other.

The only solution that I see is to machine down the step spacer that sits behind that 1 smooth idler that is closest to the tensioner. By doing so it would allow the smooth idler to move towards the bracket and hence the belt would not ride on the rear edge any longer. I don't like the idea of the belt riding close to either the front or rear edge of the idler as when the belt is under load it could catch the edge and now you either break the belt or shred it.

One other thing I forgot to mention the belt walks fore and aft on the idlers about .060 - .070 and none of the idlers a wobbling is this normal movement as I don't see it doing that on the opposite side of the drive system where the alternator and adjustable idlers sits. The belt rides bang on the center of those smooth pulleys and there is no belt walk on that side.

Awaiting your response Whipple.

Measuring with a straight edge on all these pulleys is nearly impossible because all the faces on each pulley is different. You would have to measure from the straight edge to the center of the same rib on each.

Something is out of alignment, that is the only explanation. Does the belt run true now without the shim? Before, the cast Dayco HD was as cast, we couldn't control tolerances. On the billet, it has no rock, runs true and has minimal variance on machining. Its best to remove the smooth idlers and use the laser alignment tool. You can even use the grooved idler from the tensioner in the smooth positions for measurement purposes, makes it very easy. But you normally need to measure from the crank pulley up, as it has the least amount of rock. If you measure from an idler, the bearing rock will give you inaccurate data.

You can machine the back of the idler spacer, no question, but better would be to machine the stands behind that idler, behind water pump to pull plate in, my guess this is where the issue is.

If you email me your info, I'll be happy to send you some parts out to resolve the issue.

Sponsored