Johnb-5.0

Well-Known Member

- Joined

- Jul 30, 2013

- Threads

- 10

- Messages

- 155

- Reaction score

- 28

- Location

- Kansas City Mo

- First Name

- John

- Vehicle(s)

- 2006 Volvo XC90 GT350

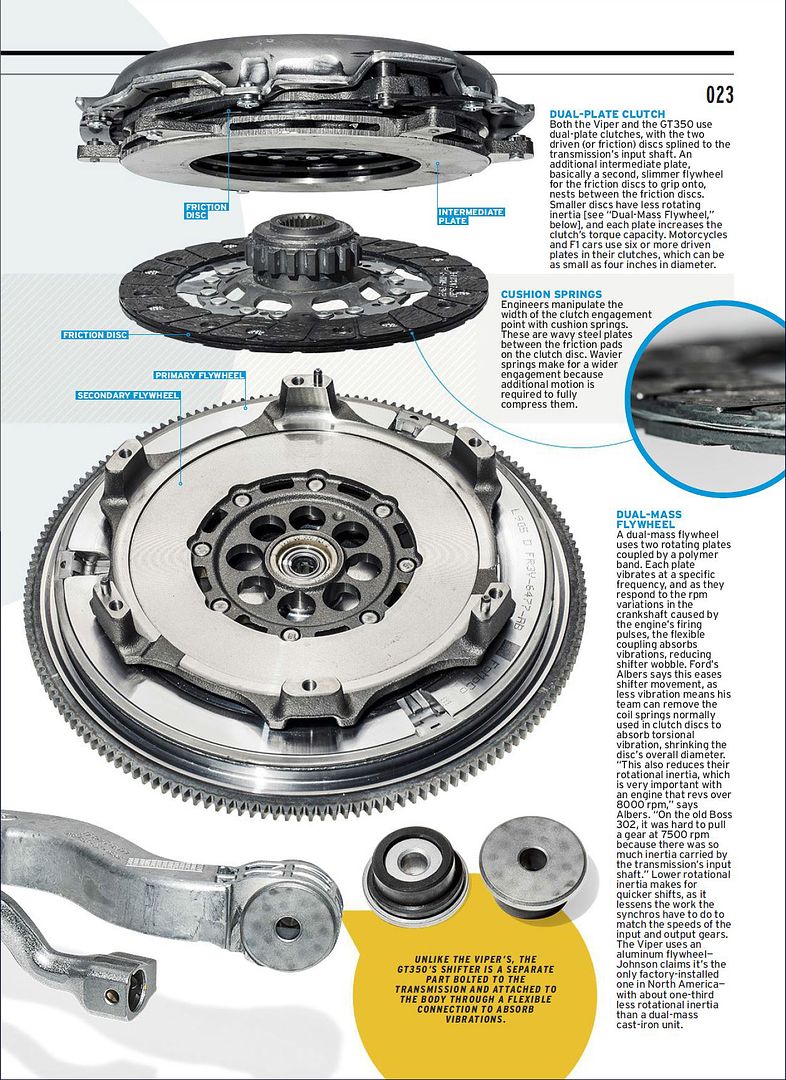

Jamal Hameedi stated they couldn't find a Carbon fiber driveshaft that was stiff enough. So is it possible that it may have negative effects with the operation of the dual mass flywheel?

Sponsored