Super Werty

Well-Known Member

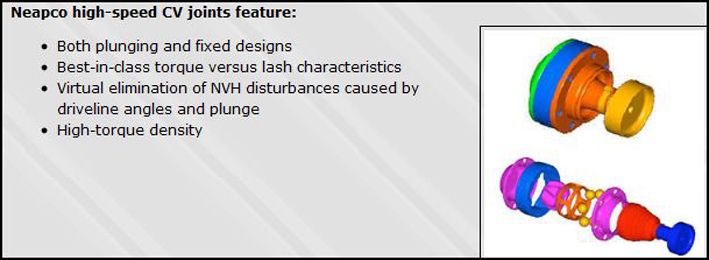

Not stiff enough? Why do all the exotic car brands have them then? It's cost related... Has to be.I had the opportunity to talk to Jamal Hameedi about why the factory didn't pick up where the last GT500 left off and include a CF shaft on the GT350 as well. He was clear that fiber shafts weren't stiff enough, hence the two piece. So I'd love to hear DSS' point of view and what they are doing differently with this specific application to make it work - properly.

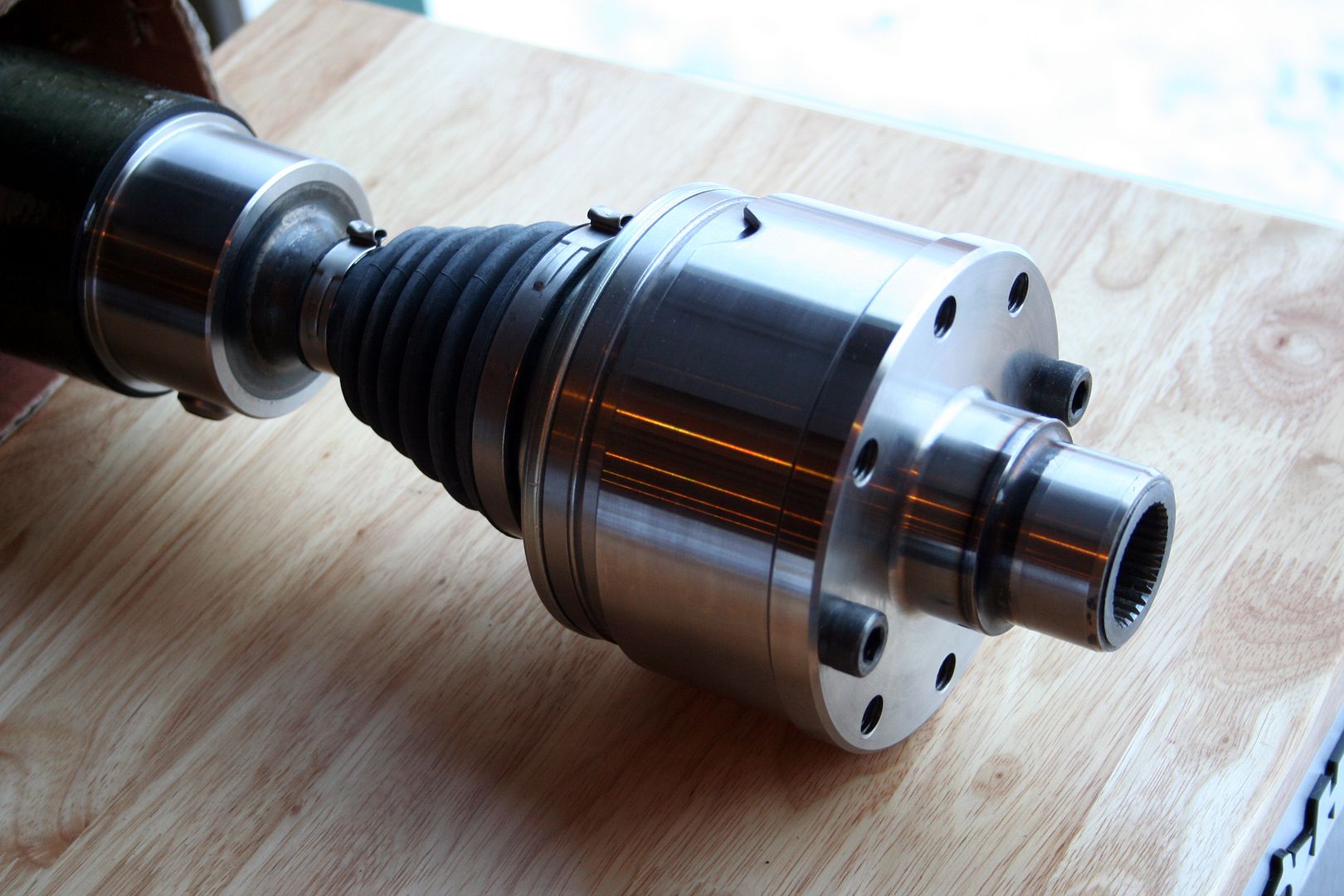

I have one and noticed a difference right away. Throttle is a bit snappier. Less slop and weight. 36 vs 18 lbs difference

Sponsored